To make an impression, parquets require perfect sanding!

To better understand what is in stake, Ahlstrom's team met the French company Chêne de l’Est and Jean-Michel Bach, one of its directors.

What are the first stages of the preparation?

JMB : When it comes in, the wood undergoes several sanding operations.

First of all we use a P80 grit belt to flatten out the undulations left by the planing process and calibrate the boards.

Then we smooth them by sanding out the scratches left by the first stage with a P100/120 grit.

These first stages are important…

JMB : They are decisive! The better they are performed, the more effectively we will be able to work on finishes like brushing or more complex ones like colouring and ageing.

For a varnished parquet, the boards are put through a denibbing machine that removes the wood fibers that have been lifted up.

For a perfect finish, we then use a P400 paper with very fine grits.

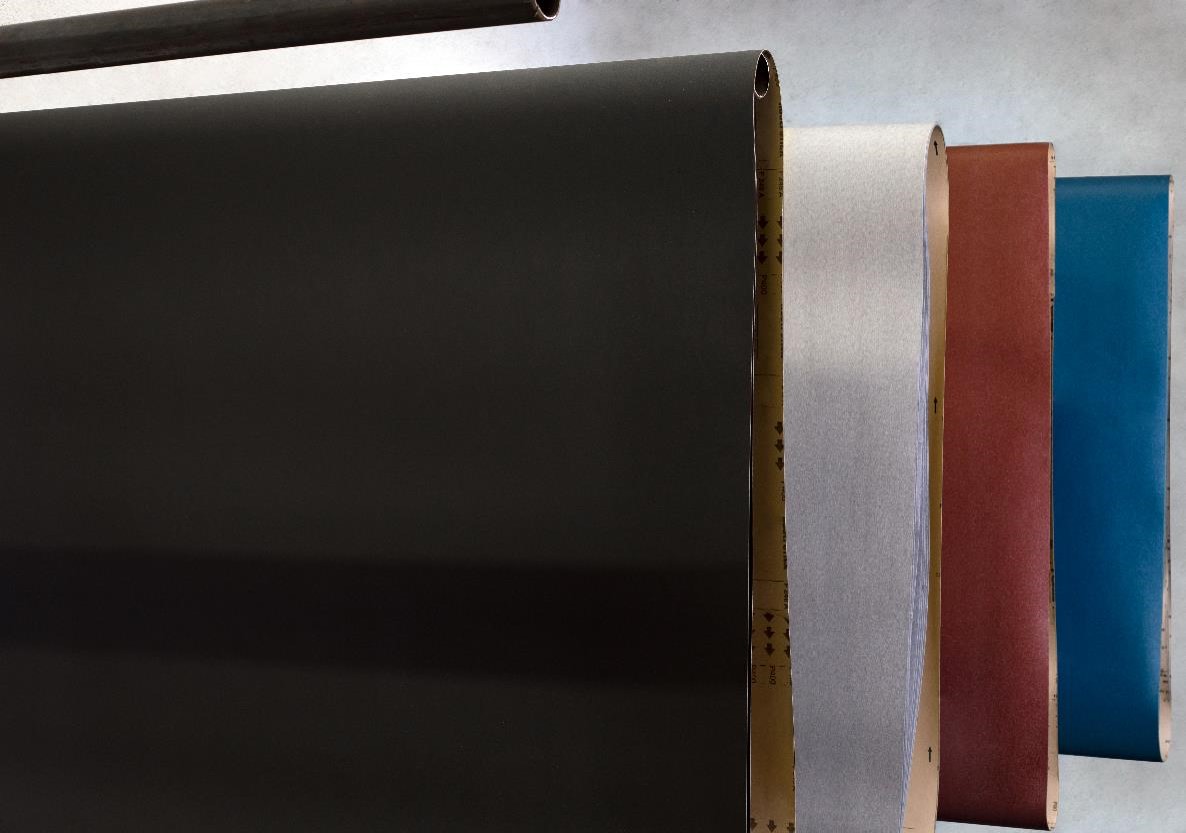

What are the qualities of a good abrasive backing?

The regularity of the grits allows us to achieve uniform sanding.

The backings also have to be very strong, to keep belt changes to a minimum, and antistatic to avoid the belts clogging up.

Finally, they have to fit the machine - that’s essential. The sanding has to be perfect for our parquet flooring to produce the desired effect!