Ahlstrom unveils new secret fibers for resinoid bonded cutting off and grinding wheels

Are you a printer looking for black heat-resistant paper solutions with high surface quality ?

A fiber-glass mesh producer looking for black stay-flat protection ?

Or a resinoid bonded cutting off and grinding wheels producers wishing to secure the supply-chain and willing to work on innovation as colours or security devices ?

Then we invite you to discover our new fiber-based solutions designed for resinoid bonded cutting off and grinding wheels.

New backings for bonded abrasives with the same quality level as for our backings for coated abrasives

«Ahlstrom quality applied to bonded abrasives: this is what manufacturers of cutting and grinding discs told us they hoped for in 2015. Always ready to listen to what the market is telling us, we decided to take advantage of synergies between our different skills and the capacities of our Machine 6 to give them what they wanted!», says Estelle Seibert, abrasive marketing manager.

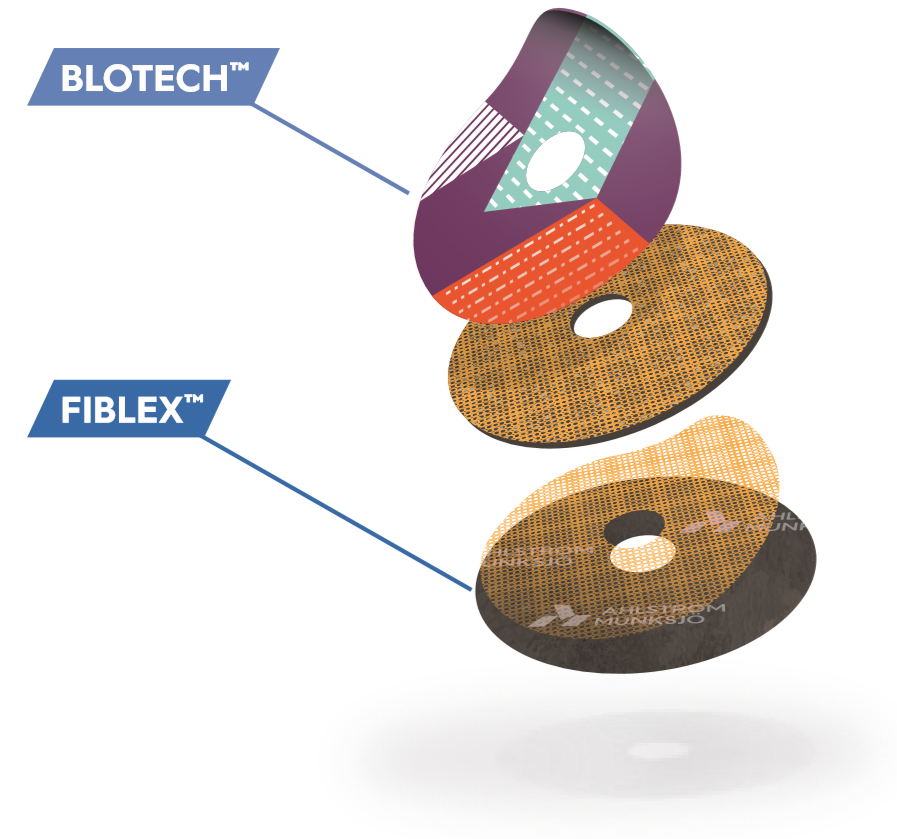

And so Ahlstrom is now able to offer two types of backings that make the most of the unlimited potential offered by fibers.

FIBLEX™- backings to layer onto fiberglass mesh

Layered onto the fiberglass mesh that will reinforce cutting disks, these backings help manufacturers to avoid clogging up their machines.

Black non-woven, paper and crepe paper prototypes are already available in grammages of 25 - 30 and 39 gsm respectively. Each type of backing offers different advantages according to the type of disc to be produced. Other grammages are possible on request.

The paper backing is «both flexible and water-repellent so that the abrasive mixture does not go through the paper and clog up the automatic machinery. Its surface quality, its low thickness, its stability and the good resistance of the black colour to heat also ensure that discs of all sizes have an excellent finish after curing.»

Even more stable, the non-woven backing is characterized by «increased flexibility and malleability that enable it to return to a perfectly flat state».

The crepe paper backing offers a compromise between the two other solutions, offering «optimum flexibility, elongation and barrier qualities».

BLOTECH™- technical paper to print heat-resistant abrasive labels

These paper backings are designed for the technical labels containing all the regulatory markings, also known as «blotters». «If stability of colour and surface are key to perfect rendering of the printing after curing and heat-induced cross-linking of the abrasive coating, the formulation of the backing also has to be suited to the inks used and the printing process.

To achieve that, we can make all the necessary adjustments with each printer». The spectrum of possibilities remains open: «imagining colours other than black, yellow for example, adding security fibers for traceability purposes, etc. It is even possible to create crepe paper labels for cup-shaped discs.»

Don’t hesitate to ask us for samples of the existing prototypes and to let us know your needs in terms of bonded abrasives: together we can create innovative, high-performance and differentiating solutions!