Antistatic treatments for abrasive papers : why? how? Measurement best-practices

Experts Coffee Break Sessions (Topic B)

Where does static electricity come from?

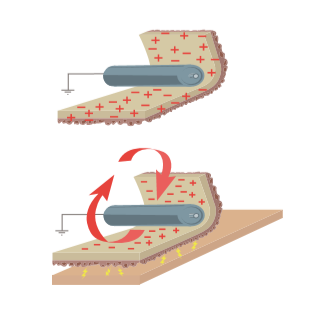

When the abrasive sanding belt is not in use, the sanding belt is in a state of equilibrium. In the atoms that make it up, the positive charge of the nucleus is equal to the negative charges of the electrons that revolve around it: the charge is said to be «neutral». During sanding the friction generated by sanding causes movement in the electrons and this creates an imbalance, which charges the surface of the materials and produces static electricity…

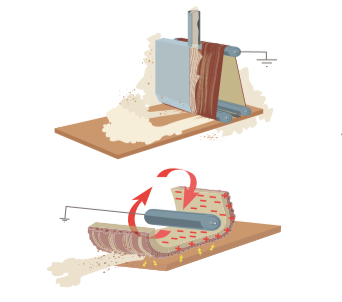

What happens when you sand with a conventional abrasive belt?

The wood and the abrasive paper are neutral materials, that is to say non-conductive. During sanding, the accumulated static charge has nowhere to go… The imbalance in the charge attracts dust, causing the abrasive paper belt to get clogged up.

What is different with an antistatic belt?

An antistatic paper belt has been treated to make it conductive. The static charge can therefore be discharged to the ground, reestablishing the balance. In this case, the paper does not attract the dust and can be removed by the extractor on the machine.

Result: the paper is not clogged up, so the belt does not need to be changed so often, and the working environment is cleaner and healthier.

👉 If you want to increase the lifetime of belts, make the sanded part cleaner and get workshop safer.

This expertise coffee break replay is for you.

Meet our abrasive experts

Technical Director @ Ahsltrom

Abrasive backing expert & 20-years experienced paper specialist focused on quality and customer satisfaction.

Abrasive R&D Manager @ Ahlstrom

30-years experienced paper engineer, PhD graduate in process engineering from the National Polytechnical Institute in Grenoble. 22 years expertise in abrasive backings development, in their chemical formulation and physical properties.